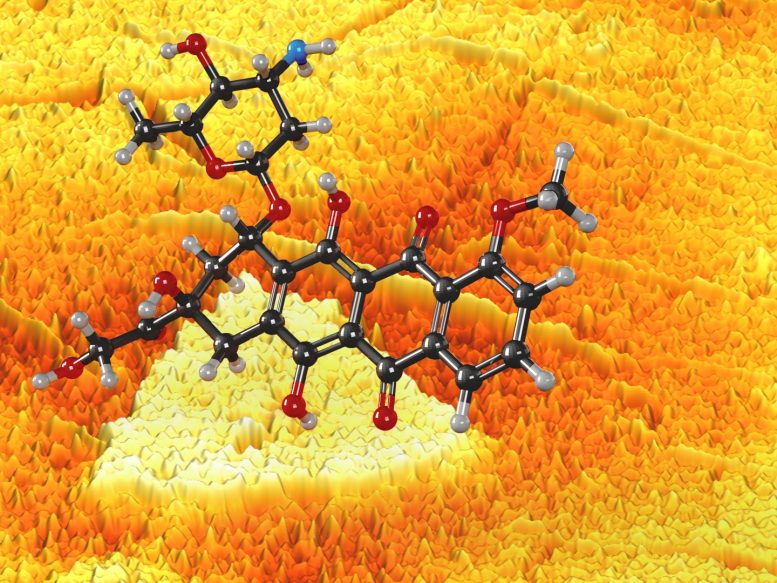

A molecule of the cancer medication doxorubicin (foreground), detected using the van der Waals vertical heterostructure biosensor (background). The background is an actual nanoscale scattering scanning near-field optical microscopy image (sSNOM) of the heterostructure and the large triangle is a single-layer MoS2 island (ca. 3.7 micron wide), the smaller triangle is a partially oxidized MoOS island, and the whole sample is covered with the monolayer graphene, with several wrinkles clearly seen in the map. The darker graphene area corresponds to the region of extra charge doping. Credit: Elizabeth Flores-Gomez Murray/Jennifer McCann/Slava Rotkin, Penn state

A novel and better approach at detecting non-uniformities in the optical properties of two-dimensional materials could potentially open the door to new uses for these materials, such as for drug detection, according to a team of researchers.

“The Two-Dimensional Crystal Consortium (2DCC) is a world leader in 2D materials research and my lab often works with the 2DCC doing materials characterization for novel 2D materials,” said Slava V. Rotkin, Frontier Professor of Engineering Science and Mechanics with an appointment in the Materials Research Institute at Penn State. “There is a big challenge in these studies: Frequently, optical properties of 2D materials are not uniform in space. Furthermore, they may vary at a very small spatial scale, down to a single

Sensors can be developed that enable sensing of bio-, chemical and/or medical analytes of interest. Analytes are specific chemicals targeted for measurement or analysis. A good sensor detects these analytes with minimal sample preparation, in an abbreviated time frame, with low detection limits, and using samples containing substances other than the key analyte.

Identifying and understanding variability of properties in materials could be extremely important for applications of 2D materials as sensors. The sensor material typically can only interact with the analyte at the surface. Thus, the material’s surface is an active area, while material’s volume is not. The larger the ratio of surface to volume, the lower the fraction of material which cannot be used. Such atomically thin materials have the ultimate surface-to-volume ratio for sensor use and may possess surface non-uniformities at the nanometer scale. This includes atomic impurities, adsorbates, defects, wrinkles, ruptures, etc. Such features can modulate the optical properties.

“Despite this being critical for effectiveness in certain application of 2D materials, there is currently no truly effective approach to detect these variabilities,” Rotkin said. “Due to their being so tiny, they are undetectable by optical tools and non-optical tools cannot resolve optical contrast.”

The researchers conducted experiments using a heterostructure material made of

Thank you for your sharing. I am worried that I lack creative ideas. It is your article that makes me full of hope. Thank you. But, I have a question, can you help me?

I don’t think the title of your article matches the content lol. Just kidding, mainly because I had some doubts after reading the article.