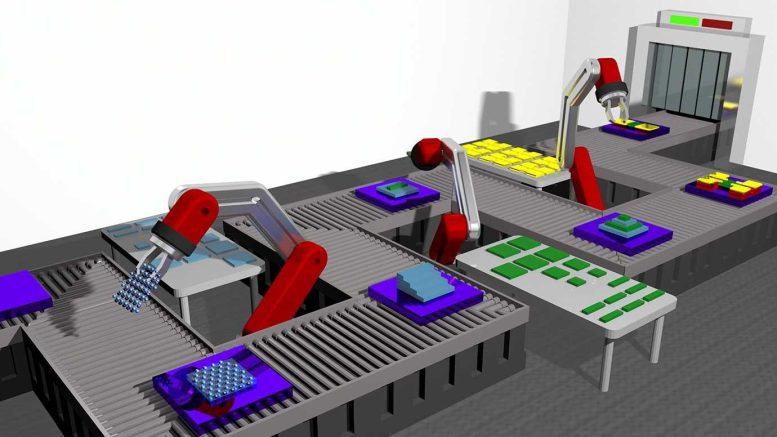

A breakthrough by University of Chicago scientists created a method to speed the search for potential new materials for electronics and other applications. Above, a conceptual rendition of “robots” stacking thin films on an assembly line. Credit: Rendering by Andrew Ye

Technique by UChicago scientists creates ‘assembly line’ for integrating new materials.

Let’s say you’re an engineer with an idea for a new car. But before you even can start experimenting, you have to spend hours casting screws and making rubber for tires from scratch.

This is similar to the challenge facing researchers trying to invent new kinds of technology. The ability to make, say, a flexible screen or a new solar panel, starts with discovering a new combination of materials with unusual properties at the atomic scale. But in the field of 2D materials, which is considered one of the most exciting areas for future electronics, scientists still have to laboriously hand-make each new potential material before they can test its capabilities.

A new technique asks a robot to lend a hand. Developed by scientists from the

Scientists used the method to create a first-of-its-kind image of the atomic “texture” of a crystal assembled with four degrees of rotation between four layers. Credit: Image courtesy Mannix et al.

They wanted to make a sort of tiny assembly line, but each component of the manufacturing process came with its own challenges. First, the scientists had to figure out a way to precisely cut their sheets into the exact shapes they wanted, which is difficult to do cleanly without breaking or damaging the sheets. “With experimentation, we found a technique that could achieve large-area patterning, with very high precision and without contaminating the material,” said Andrew Ye, a Ph.D. student in Park’s lab and the other co-first author of the paper.

The next challenge was making a robot “hand” capable of maneuvering these extremely fragile sheets. “I needed to find a polymer that was precise enough to pick up the sheets,” said Mannix, “but also capable of letting it down again—gently and in the exact right spot.”

They came up with a “hand” made of soft polymers that fall apart when exposed to heat or ultraviolet light. Once the sheet is precisely positioned, the hand dissolves and the sheet drops into place.

With this system, the scientists could now program their assembly line to make a material structure with dozens of different layers, walk away, and come back to a finished sample ready to test in a matter of minutes.

Not only is the system very precise, but it also offers extensive options for customization, including the coveted ability to rotate each successive sheet at different angles.

“When we started looking at this problem, it seemed unimaginable to automate it,” said Park, who is appointed in both the Department of Chemistry and the Pritzker School of Molecular Engineering. “This should speed up the pace of discovery considerably. It’s kind of like the difference between handwriting a book letter by letter versus using a printing press.”

Reference: “Robotic Four-Dimensional Pixel Assembly of van der Waals Solids” by Andrew J. Mannix, Andrew Ye, Suk Hyun Sung, Ariana Ray, Fauzia Mujid, Chibeom Park, Myungjae Lee, Jong-Hoon Kang, Robert Shreiner, Alexander A. High, David A. Muller, Robert Hovden and Jiwoong Park, 24 January 2022, Nature Nanotechnology.DOI: 10.1038/s41565-021-01061-5

The other authors on the study included University of Chicago graduate students Fauzia Mujid and Robert Shreiner; postdoctoral researchers Myungjae Lee and Jong-Hoon Kang; Chibeom Park, formerly a postdoctoral researcher and now at the Samsung Electronics Semiconductor Research Center; Prof. Alex High of the Pritzker School of Molecular Engineering and Argonne National Laboratory; Ariana Ray and Prof. David Muller of Cornell; and Suk Hyun Sung and Prof. Robert Hovden of the University of Michigan.

The research made use of the University Chicago Materials Research Science and Engineering Center, the Pritzker Nanofabrication Facility, the Searle Cleanroom, the Michigan Center for Materials Characterization, and the Cornell Center for Materials Research.

Funding: National Science Foundation, Air Force Office of Scientific Research, Samsung Advanced Institute of Technology, Department of Defense, W.M. Keck Foundation, Army Research Office.

I may need your help. I tried many ways but couldn’t solve it, but after reading your article, I think you have a way to help me. I’m looking forward for your reply. Thanks.

361477 781254Yay google is my king helped me to uncover this great internet internet site ! . 832534

981111 240424Glad to be one of many visitants on this wonderful internet internet site : D. 294006

169583 939302You produced some decent points there. I looked online for the issue and identified a lot of people could go as effectively as utilizing your internet website. 141393

36362 336688Yay google is my world beater aided me to discover this outstanding web site! . 747785

589289 247013You must take part in a contest for among the finest blogs on the web. I will recommend this web site! 385743

950488 58449I always check out your blog and retrieve everything you post here but I never commented but today when I saw this post, I couldnt stop myself from commenting here. Amazing article mate! 259722

376819 115848Hiya! awesome weblog! I happen to be a day-to-day visitor to your web site (somewhat much more like addict ) of this internet site. Just wanted to say I appreciate your blogs and am searching forward for much more to come! 273506