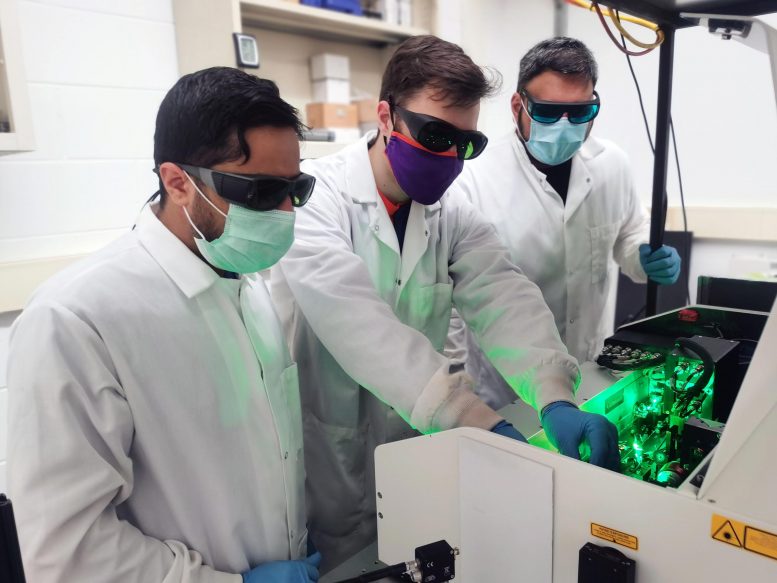

From left, Pan Adhikari, Lawrence Coleman and Kanishka Kobbekaduwa align the ultrafast laser in the Department of Physics and Astronomy’s UPQD lab. Credit: Clemson University

By using laser spectroscopy in a photophysics experiment, Clemson University researchers have broken new ground that could result in faster and cheaper energy to power electronics.

This novel approach, using solution-processed perovskite, is intended to revolutionize a variety of everyday objects such as solar cells, LEDs, photodetectors for smartphones and computer chips. Solution-processed perovskites are the next generation materials for solar cell panels on rooftops, X-ray detectors for medical diagnosis, and LEDs for daily-life lighting.

The research team included a pair of graduate students and one undergraduate student who are mentored by Jianbo Gao, group leader of Ultrafast Photophysics of Quantum Devices (UPQD) group in the College of Science’s Department of Physics and Astronomy.

The collaborative research was published March 12 in the high-impact journal Nature Communications. The article is titled “In-situ Observation of Trapped Carriers in Organic Metal Halide Perovskite Films with Ultra-fast Temporal and Ultra-high Energetic Resolutions.”

The principal investigator was Gao, who is an assistant professor of condensed matter physics. The co-authors included graduate students Kanishka Kobbekaduwa (first author) and Pan Adhikari of the UPQD group, as well as undergraduate Lawrence Coleman, a senior in the physics department.

Other authors from Clemson were Apparao Rao, the R.A. Bowen Professor of Physics, and Exian Liu, a visiting student from China who works under Gao.

“Perovskite materials are designed for optical applications such as solar cells and LEDs,” said Kobbekaduwa, a graduate student and first author of the research article. “It is important because it is much easier to synthesize compared to current silicon-based solar cells. This can be done by solution processing — whereas in silicon, you have to have different methods that are more expensive and time-consuming.”

The goal of the research is to make materials that are more efficient, cheaper and easier to produce.

The unique method used by Gao’s team — employing ultrafast photocurrent spectroscopy — allowed for a much higher time resolution than most methods, in order to define the physics of the trapped carriers. Here, the effort is measured in picoseconds, which are one trillionth of a second.

“We make devices using this (perovskite) material and we use a laser to shine light on it and excite the electrons within the material,” Kobbekaduwa said. “And then by using an external electric field, we generate a photocurrent. By measuring that photocurrent, we can actually tell people the characteristics of this material. In our case, we defined the trapped states, which are defects in the material that will affect the current that we get.”

Once the physics are defined, researchers can identify the defects — which ultimately create inefficiency in the materials. When the defects are reduced or passivated, this can result in increased efficiency, which is critical for solar cells and other devices.

As materials are created through solution processes such as spin coating or inkjet printing, the likelihood of introducing defects increases. These low temperature processes are cheaper than ultra-high temperature methods that result in a pure material. But the tradeoff is more defects in the material. Striking a balance between the two techniques can mean higher-quality and more efficient devices at lower costs.

The substrate samples were tested by shooting a laser at the material to determine how the signal propagates through it. Using a laser to illuminate the samples and collect the current made the work possible and differentiated it from other experiments that do not employ the use of an electric field.

“By analyzing that current, we are able to see how the electrons moved and how they come out of a defect,” said Adhikari of the UPQD group. “It is possible only because our technique involves ultrafast time scale and in-situ devices under an electrical field. Once the electron falls into the defect, those who experiment using other techniques cannot take that out. But we can take it out because we have the electric field. Electrons have charge under the electric field, and they can move from one place to another. We are able to analyze their transport from one point to another inside the material.”

That transport and the effect of material defects upon it can impact the performance of those materials and the devices in which they are used. It is all part of the important discoveries that students are making under the guidance of their mentor, creating ripples that will lead to the next great breakthrough.

“The students are not only learning; they are actually doing the work,” Gao said. “I am fortunate to have talented students who — when inspired by challenges and ideas — will become influential researchers. This is all part of the important discoveries that students are making under the guidance of their mentors, creating ripples that will lead to the next great breakthrough. We are also very grateful for the strong collaborations with Shreetu Shrestha and Wanyi Nie, who are top materials scientists from Los Alamos National Laboratory.”

Reference: “In-situ observation of trapped carriers in organic metal halide perovskite films with ultra-fast temporal and ultra-high energetic resolutions” by Kanishka Kobbekaduwa, Shreetu Shrestha, Pan Adhikari, Exian Liu, Lawrence Coleman, Jianbing Zhang, Ying Shi, Yuanyuan Zhou, Yehonadav Bekenstein, Feng Yan, Apparao M. Rao, Hsinhan Tsai, Matthew C. Beard, Wanyi Nie and Jianbo Gao, 12 March 2021, Nature Communications.DOI: 10.1038/s41467-021-21946-2

Support for this project was provided by the Center for Integrated Nanotechnology at Los Alamos National Laboratory in Los Alamos, New Mexico, as well as the South Carolina Research Authority.