Credit: KBR, Brooks in San Antonio, Texas

Safety is paramount for NASA’s quiet supersonic flight team who are making great strides in preparing for future flight testing with the X-59 Quiet SuperSonic Technology (QueSST) aircraft. To achieve the safest possible environment and aircraft for our pilots, NASA is working with contractor KBR and relying on their expertise to make sure that the aircraft is meeting required standards for the life support and emergency oxygen systems.

NASA’s X-59 is a research aircraft designed to take the “boom” out of the sonic boom with its quiet supersonic technologies and design features. The Low-Boom Flight Demonstration mission is reshaping supersonic flight by helping to change the existing aviation rules by collecting community feedback on the gentle thump that they hear when the X-59 flies overhead. This data will then be shared with federal and international regulators to enable them to consider setting new guidelines for supersonic travel over land. To get to this phase of the project, the team needs to ensure that the X-59’s life support system is effective in providing the protection needed to enable flight at the high altitudes required to meet its mission.

To ensure the X-59 pilot’s safety, the sophisticated life support system equipment is undergoing a series of tests that include simulating an unlikely cabin depressurization.

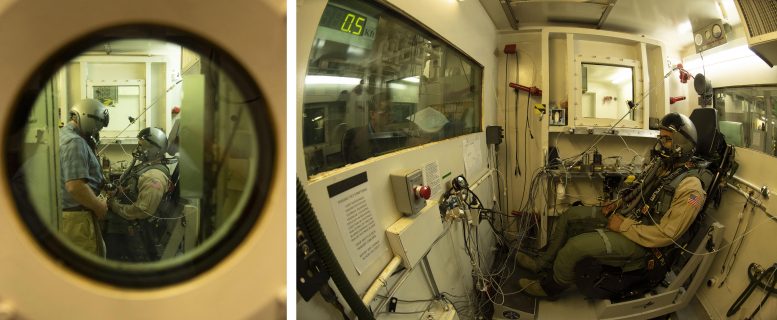

Pictured at left: The low pressure (hypobaric) chamber at KBR’s facility in San Antonio, Texas, simulates very high altitudes by reducing the air pressure inside of the chamber. The subject inside the chamber experiences the reduced pressure conditions that exist at higher altitudes, in this case altitudes up to 60,000 feet.

Pictured at right: A military test volunteer wears protective equipment while breathing oxygen before undergoing a rapid decompression. The goal of the test to verify the equipment that he uses and wears, as well as the life support system, all work properly.

Military test volunteers are constantly monitored by a team of experts as a live stream of this activity and its data are displayed on monitors. The physiology of the test volunteers is also tracked, and there is a medical professional on-site in the unlikely event that their health requires attention.

Rapid decompression testing up to either 50,000 or 60,000 feet in the air makes sure the pilot can survive a sudden loss of pressure at the X-59’s cruising altitude by providing oxygen under high pressure to the pilot’s lungs – to prevent damage to the lungs, the volunteer and pilot must wear a counter-pressure vest and pants. This altitude is more than 20,000 feet higher than the altitude at which commercial airplanes fly. Typically, commercial airline flight passengers experience pressure at altitudes of up to only 8,000 feet. As part of this test, the test volunteer descends back down to ground level at pre-determined rates. Continuous monitoring by the test team ensures proper function of the protective equipment as well as the health and safety of the volunteer.

The primary oxygen system testing is now complete, with testing to follow on the X-59’s emergency oxygen system. After completion, the systems will be placed on the X-59 and the team will administer additional checkouts after installation.