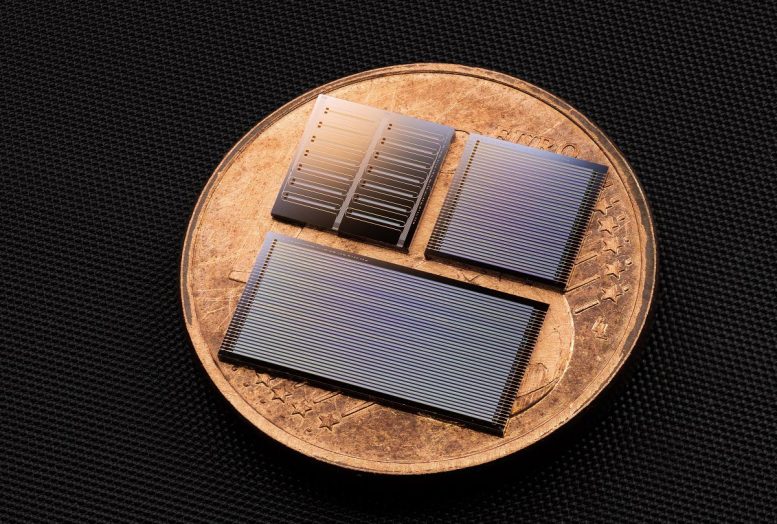

Lithium tantalate photonic integrated circuits. Credit: Tobias Kippenberg (EPFL)

New photonic integrated circuit technology based on lithium tantalate improves cost-efficiency and scalability, making significant advancements in optical communications and computing.

Optical communications and computing systems have been revolutionized by the rapid advancement in photonic integrated circuits (PICs), which combine multiple optical devices and functionalities on a single chip.

For decades, silicon-based PICs have dominated the field due to their cost-effectiveness and their integration with existing semiconductor manufacturing technologies, despite their limitations with regard to their electro-optical modulation bandwidth. Nevertheless, silicon-on-insulator optical transceiver chips were successfully commercialized, driving information traffic through millions of glass fibers in modern data centers.

Emerging Lithium Niobate Platforms

Recently, the lithium niobate-on-insulator wafer platform has emerged as a superior material for photonic integrated electro-optical modulators due to its strong Pockels coefficient, which is essential for high-speed optical modulation. Nonetheless, high costs and complex production requirements, have kept lithium niobate from being adopted more widely, limiting its commercial integration.

Lithium tantalate (LiTaO3), a close relative of lithium niobate, promises to overcome these barriers. It features similar excellent electro-optic qualities but has an advantage over lithium niobate in scalability and cost, as it is already being widely used in 5G radiofrequency filters by telecom industries.

Now scientists led by Professor Tobias J. Kippenberg at EPFL and Professor Xin Ou at the Shanghai Institute of Microsystem and Information Technology (SIMIT) have created a new PIC platform based on lithium tantalate. The PIC leverages the material’s inherent advantages and can transform the field by making high-quality PICs more economically viable. The breakthrough was published on May 8 in Nature.

Technological Innovations in Fabrication

The researchers developed a wafer-bonding method for lithium tantalate, which is compatible with silicon-on-insulator production lines. They then masked the thin-film lithium tantalate wafer with diamond-like carbon and proceeded to etch optical waveguides, modulators, and ultra-high quality factor microresonators.

The etching was achieved by combining deep ultraviolet (DUV) photolithography and dry-etching techniques, developed initially for lithium niobate and then carefully adapted to etch the harder and more inert lithium tantalate. This adaptation involved optimizing the etch parameters to minimize optical losses, a crucial factor in achieving high performance in photonic circuits.

Achievements and Future Prospects

With this approach, the team was able to fabricate high-efficiency lithium tantalate PICs with an optical loss rate of just 5.6 dB/m at telecom wavelength. Another highlight is the electro-optic Mach-Zehnder modulator (MZM), a device widely used in today’s high-speed optical fiber communication. The lithium tantalate MZM offers a half-wave voltage-length product of 1.9 V cm and an electro-optical bandwidth reaching 40 GHz.

“While maintaining highly efficient electro-optical performance, we also generated soliton microcomb on this platform,” says Chengli Wang, the study’s first author. “These soliton microcombs feature a large number of coherent frequencies and, when combined with electro-optic modulation capabilities, are particularly suitable for applications such as parallel coherent LiDAR and photonic computing.”

The lithium tantalate PIC’s reduced birefringence (the dependence of refractive index on light polarization and propagation direction) allows dense circuit configurations and ensures broad operational capabilities across all telecommunication bands. The work paves the way for scalable, cost-effective manufacturing of advanced electro-optical PICs.

Reference: “Lithium tantalate photonic integrated circuits for volume manufacturing” by Chengli Wang, Zihan Li, Johann Riemensberger, Grigory Lihachev, Mikhail Churaev, Wil Kao, Xinru Ji, Junyin Zhang, Terence Blesin, Alisa Davydova, Yang Chen, Kai Huang, Xi Wang, Xin Ou and Tobias J. Kippenberg, 8 May 2024, Nature.DOI: 10.1038/s41586-024-07369-1

Source: SciTechDaily