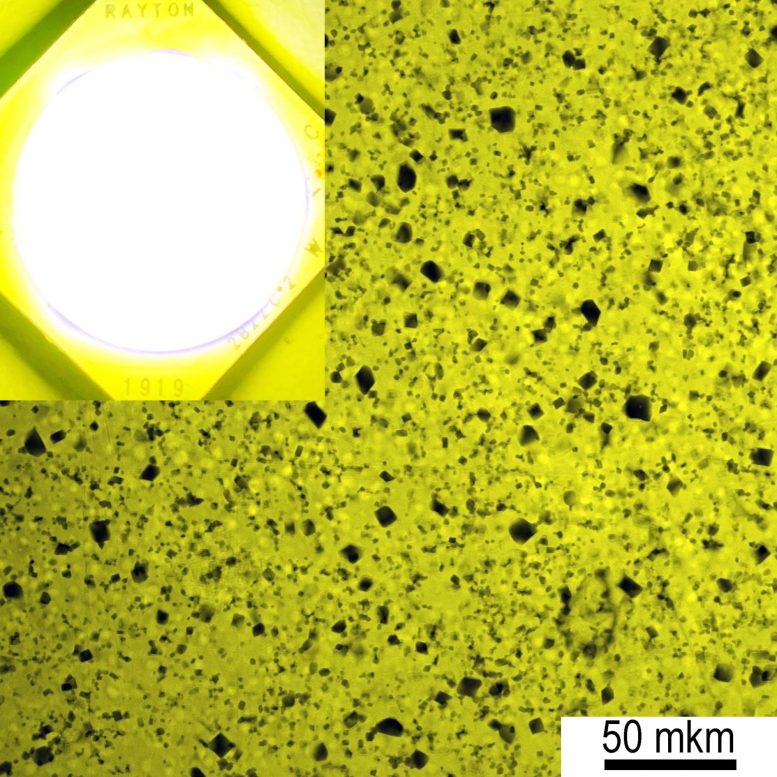

The microstructure of a composite ceramic phosphor, and the appearance of an LED device based on. Credit: Denis Kosyanov, FEFU

Materials scientists at Far Eastern Federal University (FEFU), in collaboration with an international research team, have advanced the design of composite ceramic materials (Ce3+:YAG-Al2O3), i.e. solid-state light converters (phosphors) that can be applied in-ground and aerospace technologies. The LED systems based on the developed materials can save 20-30 percent more energy compared to commercial analogs. A related article was published in the journal Materials Characterization.

Over 15% of the total global electricity production, or about $ 450 billion annually, is spent on lighting. According to the photonics development roadmap run in Russia, the development of LED technology with an efficiency of more than 150 lm/W will allow for the savings of up to 30% of electricity by 2025.

Based on the developed ceramic light converters, it is possible to produce both compact energy-efficient white light-emitting diodes (wLEDs) and high-power (high brightness) systems. The new material is in demand for many photonic applications from portable projectors and endoscopes to laser TVs with a diagonal of more than 100 inches, lighting devices for auto and aircraft construction, megastructures, etc.

“The consumption of white LEDs is more than half of the total consumption of high brightness LEDs. Some peculiarities of the technology for the production of organic phosphors for modern commercial white LEDs lead to the quick aging of the light-emitting diode that loses brightness and quality of color rendering. We get around the problem by creating completely inorganic light converters in the form of composite ceramics based on yttrium aluminum garnet, activated by cerium ions Ce3+:YAG, and a thermally stable phase of aluminum oxide Al2O3,” says Anastasia Vornovskikh, a Junior Researcher at the REC for “Advanced Ceramic Materials” of the FEFU Polytechnic Institute (school, PI).

The new materials are characterized by high values of thermal strength and thermal conductivity, endure high pumping power, and generate bright white light without obvious thermal quenching of the photoluminescence intensity. This makes it possible to reduce the operating temperature of the LED device down to 120-70°C, more than 2 times in comparison with commercial samples of Ce3+:YAG.

“We synthesized materials by vacuum reactive sintering of initial oxide powders of aluminum, yttrium, cerium, and gadolinium. Particular attention we paid to the identification of the quantitative relationship between the main scattering centers that are residual pores and Al2O3 crystallites and the spectroscopic properties of ceramic phosphors. Our light converters meet all the requirements for new generation wLEDs. They have a long lifespan, high luminous efficacy and color rendering index while maintaining the requirements for the environmental friendliness and material dimensions,” says project manager Denis Kosyanov, Director of the REC for “Advanced Ceramic Materials,” of the Industrial Safety Department of FEFU PI.

In the study took part researchers from Far Eastern Federal University (FEFU); Shanghai Institute of Ceramics, the Shanghai Technological Institute, the University of the Chinese Academy of Sciences; Institute of Chemistry of the Far Eastern Branch of the Russian Academy of Sciences; Institute of Solid State Chemistry and Mechanochemistry of the Siberian Branch of the Russian Academy of Sciences.

Reference: “Al2O3–Ce:YAG and Al2O3–Ce:(Y,Gd)AG composite ceramics for high brightness lighting: Effect of microstructure” by D. Yu. Kosyanov,Xin Liu, A. A. Vornovskikh, A. A. Kosianova, A. M. Zakharenko, A. P. Zavjalov, O. O. Shichalin, V. Yu. Mayorov, V. G. Kuryavyi, Xinglu Qian, Jun Zou and Jiang Li, 6 January 2021, Materials Characterization.DOI: 10.1016/j.matchar.2021.110883

This work was financially supported by the Russian Science Foundation (Project No. 20-73-10242).