The Rapid Agent Aerosol Detector was photographed with a 12-inch ruler to illustrate scale. Credit: Courtesy of the researchers

The Rapid Agent Aerosol Detector developed at Lincoln Laboratory has demonstrated excellent accuracy in identifying toxic biological particles suspended in the air.

Any space, enclosed or open, can be vulnerable to the dispersal of harmful airborne biological agents. Silent and near-invisible, these bioagents can sicken or kill living things before steps can be taken to mitigate the bioagents’ effects. Venues where crowds congregate are prime targets for biowarfare strikes engineered by terrorists, but expanses of fields or forests could be victimized by an aerial bioattack. Early warning of suspicious biological aerosols can speed up remedial responses to releases of biological agents; the sooner cleanup and treatment begin, the better the outcome for the sites and people affected.

MIT Lincoln Laboratory researchers have developed a highly sensitive and reliable trigger for the U.S. military’s early warning system for biological warfare agents.

“The trigger is the key mechanism in a detection system because its continual monitoring of the ambient air in a location picks up the presence of aerosolized particles that may be threat agents,” says Shane Tysk, principal investigator of the laboratory’s bioaerosol trigger, the Rapid Agent Aerosol Detector (RAAD), and a member of the technical staff in the laboratory’s Advanced Materials and Microsystems Group.

The trigger cues the detection system to collect particle specimens and then to initiate the process to identify particles as potentially dangerous bioagents. The RAAD has demonstrated a significant reduction in false positive rates while maintaining detection performance that matches or exceeds that of today’s best deployed systems. Additionally, early testing has shown that the RAAD has significantly improved reliability compared to currently deployed systems.

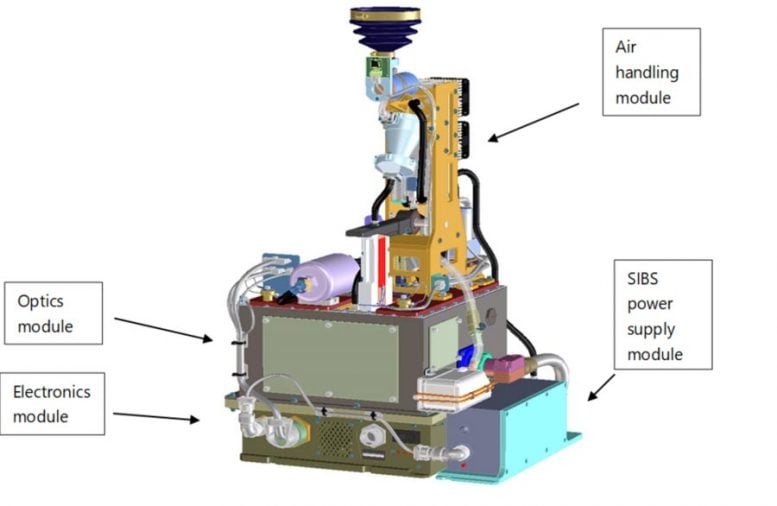

This illustration of the RAAD system shows its various modules that are mounted at the outskirts of the system for easy access for maintenance or replacement. Credit: Courtesy of the researchers

RAAD process

The RAAD determines the presence of biological warfare agents through a multistep process. First, aerosols are pulled into the detector by the combined agency of an aerosol cyclone that uses high-speed rotation to cull out the small particles, and an aerodynamic lens that focuses the particles into a condensed (i.e., enriched) volume, or beam, of aerosol. The RAAD aerodynamic lens provides more efficient aerosol enrichment than any other air-to-air concentrator.

Then, a near-infrared (NIR) laser diode creates a structured trigger beam that detects the presence, size, and trajectory of an individual aerosol particle. If the particle is large enough to adversely affect the respiratory tract — roughly 1 to 10 micrometers — a 266-nanometer ultravolet (UV) laser is activated to illuminate the particle, and multiband laser-induced fluorescence is collected.

The detection process continues as an embedded logic decision, referred to as the “spectral trigger,” uses scattering from the NIR light and UV fluorescence data to predict if the particle’s composition appears to correspond to that of a threat-like bioagent. “If the particle seems threat-like, then spark-induced breakdown spectroscopy is enabled to vaporize the particle and collect atomic emission to characterize the particle’s elemental content,” says Tysk.

Spark-induced breakdown spectroscopy is the last measurement stage. This spectroscopy system measures the elemental content of the particle, and its measurements involve creating a high-temperature plasma, vaporizing the aerosol particle, and measuring the atomic emission from the thermally excited states of the aerosol.

The measurement stages — structured trigger beam, UV-excited fluorescence, and spark-induced breakdown spectroscopy — are integrated into a tiered system that provides seven measurements on each particle of interest. Of the hundreds of particles entering the measurement process each second, a small subset of particles are down-selected for measurement in all three stages. The RAAD algorithm searches the data stream for changes in the particle set’s temporal and spectral characteristics. If a sufficient number of threat-like particles are found, the RAAD issues an alarm that a biological aerosol threat is present.

RAAD design advantages

“Because RAAD is intended to be operated 24 hours a day, seven days a week for long periods, we incorporated a number of features and technologies to improve system reliability and make the RAAD easy to maintain,” says Brad Perkins, another staff member on the RAAD development team. For example, Perkins goes on to explain, the entire air-handling unit is a module that is mounted on the exterior of the RAAD to allow for easy servicing of the items most likely to need replacement, such as filters, the air-to-air concentrator, and pumps that wear out with use.

To improve detection reliability, the RAAD team chose to use carbon-filtered, HEPA-filtered, and dehumidified sheathing air and purge air (compressed air that pushes out extraneous gases) around the optical components. This approach ensures that contaminants from the outside air do not deposit onto the optical surfaces of the RAAD, potentially causing reductions in sensitivity or false alarms.

The RAAD has undergone more than 16,000 hours of field testing, during which it has demonstrated an extremely low false-alarm rate that is unprecedented for a biological trigger with such a high level of sensitivity. “What sets RAAD apart from its competitors is the number, variety, and fidelity of the measurements made on each individual aerosol particle,” Tysk says. These multiple measurements on individual aerosol particles as they flow through the system enable the trigger to accurately discriminate biological warfare agents from ambient air at a rapid rate. Because RAAD does not name the particular bioagent detected, further laboratory testing of the specimen would have to be done to determine its exact identity.

The RAAD was developed under sponsorship from the Defense Threat Reduction Agency and Joint Program Executive Office for CBRN Defense. The technology is currently being transitioned for production from Lincoln Laboratory to Chemring Sensors and Electronic Systems.