Researchers have developed a lithium-ion battery that is fully stretchable, using an electrolyte layer capable of expanding by 5000% and maintaining charge capacity across nearly 70 charge/discharge cycles. (Artist’s concept.) Credit: SciTechDaily.com

A newly developed stretchable lithium-ion battery retains efficient charge storage after 70 cycles and expands up to 5000%. This innovation caters to the growing demand for batteries in wearable electronics, ensuring flexibility and durability.

When you think of a battery, you probably don’t think of something stretchy. However, batteries will need this shape-shifting quality to be incorporated into flexible electronics, which are gaining traction for wearable health monitors. Now, researchers in ACS Energy Letters report a lithium-ion battery with entirely stretchable components, including an electrolyte layer that can expand by 5000%, and it retains its charge storage capacity after nearly 70 charge/discharge cycles.

Advancements in Flexible Electronics

Electronics that bend and stretch need batteries with similar properties. Most researchers who have attempted to build such batteries created them with woven conductive fabric or rigid components folded into expandable shapes, similar to origami. But for a truly malleable battery, every part — the electrodes that collect charge and the charge-balancing middle electrolyte layer — must be elastic.

So far, truly stretchy battery prototypes have moderate elasticity, complex assembly processes, or limited energy storage capacity, especially over time with repeated charging and discharging. The latter can be due to a weak connection between the electrolyte layer and electrodes or instability of the fluid electrolyte, which can move around when the battery changes shape. So, rather than using a liquid, Wen-Yong Lai and coworkers wanted to incorporate the electrolyte into a polymer layer fused between two flexible electrode films, to create a completely solid, stretchy battery.

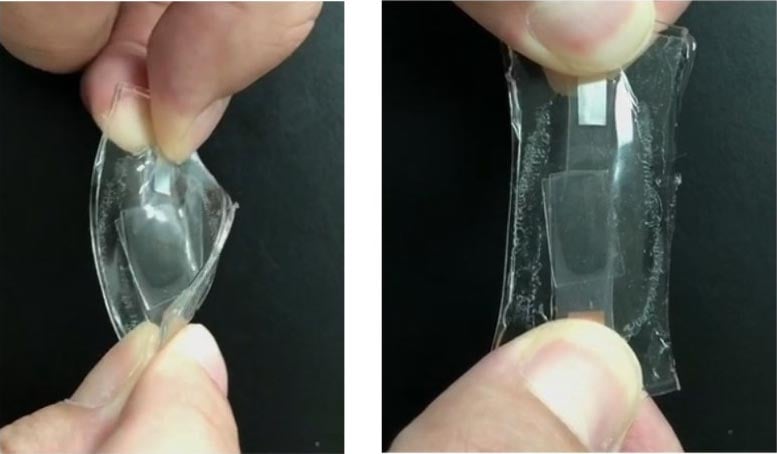

This lithium-ion battery has entirely stretchable components and stable charging and discharging capacity over time. Credit: Adapted from ACS Energy Letters 2024, DOI: 10.1021/acsenergylett.4c01254

Developing Fully Elastic Batteries

To make the electrodes for the fully elastic battery, the team spread a thin film of conductive paste containing silver nanowires, carbon black, and lithium-based cathode or anode materials onto a plate. A layer of polydimethylsiloxane, a flexible material commonly used in contact lenses, was then applied to the top of the paste. Directly on top of this film, the researchers added a lithium salt, a highly conductive liquid, and the ingredients to make a stretchy polymer.

When activated by light, these components combined to form a solid, rubbery layer capable of stretching to 5000% of its original length and able to transport lithium ions. Finally, the stack was topped with another electrode film, and the whole device was sealed in a protective coating.

Enhanced Performance and Stability

When comparing the solid stretchy battery design to a similar device with a traditional liquid electrolyte, the new version had about six times higher average charge capacity at a fast-charging rate. Likewise, the solid battery maintained a more stable capacity while operating during 67 charging and discharging cycles. In other prototypes made with solid electrodes, the polymer electrolyte maintained steady operation over 1000 cycles, with capacity dropping by 1% in the first 30 cycles, compared to a 16% drop for the liquid electrolyte.

There are still improvements to be made, but this new way of creating fully stretchable, solid batteries could be a promising step forward for wearable or implantable devices that flex and move with the body.

Reference: “Elastic Polymer Electrolytes Integrated with In Situ Polymerization-Transferred Electrodes toward Stretchable Batteries” by Shi Wang, Shijun Xiao, Henan Cai, Wenqing Sun, Tong Wu, Yu Wang, Jixin He, Sheng Yang, Zhen-Dong Huang and Wen-Yong Lai, 17 July 2024, ACS Energy Letters.DOI: 10.1021/acsenergylett.4c01254

The authors acknowledge funding from the National Key Research and Development Program of China; the National Natural Science Foundation of China; the Natural Science Foundation of Jiangsu Province; the Foundation of Key Laboratory Flexible Electronics of Zhejiang Province; Program for Jiangsu Specially-Appointed Professor; NUPT “1311 Project” and Scientific Foundation; China Postdoctoral Science Foundation; the Project of State Key Laboratory of Organic Electronics and Information Displays, NJUPT; and the Natural Science Foundation of NJUPT.

Source: SciTechDaily