Researchers developed a new 3D printing method called blurred tomography that can rapidly produce microlenses with commercial-level optical quality. They used the technique to print a microlens array, which is shown being held by a set of tweezers. Credit: Daniel Webber, National Research Council of Canada

New 3D printing method produces commercial grade microlenses with smooth surfaces, which could advance optical device design.

Researchers in Canada have developed a new 3D printing method called blurred tomography that can rapidly produce microlenses with commercial-level optical quality. The new method may make it easier and faster to design and fabricate a variety of optical devices.

“We purposely added optical blurring to the beams of light used for this 3D printing method to manufacture precision optical components,” said Daniel Webber from the National Research Council of Canada. “This enables production of optically smooth surfaces.”

In Optica, Optica Publishing Group’s journal for high-impact research, these researchers demonstrate the new method by using it to make a millimeter-sized plano-convex optical lens with an imaging performance similar to a commercially available glass lens. They also show that the method can produce optical components that are ready to use in just 30 minutes.

“We anticipate this method to be valuable for cost-effective and swift prototyping of optical components due to the affordability of the tomographic 3D printer and the materials used,” said Webber. “Also, the inherent freeform nature of tomographic 3D printing could enable optical designers to simplify designs by replacing multiple standard optics with printed optics that have complex shapes.”

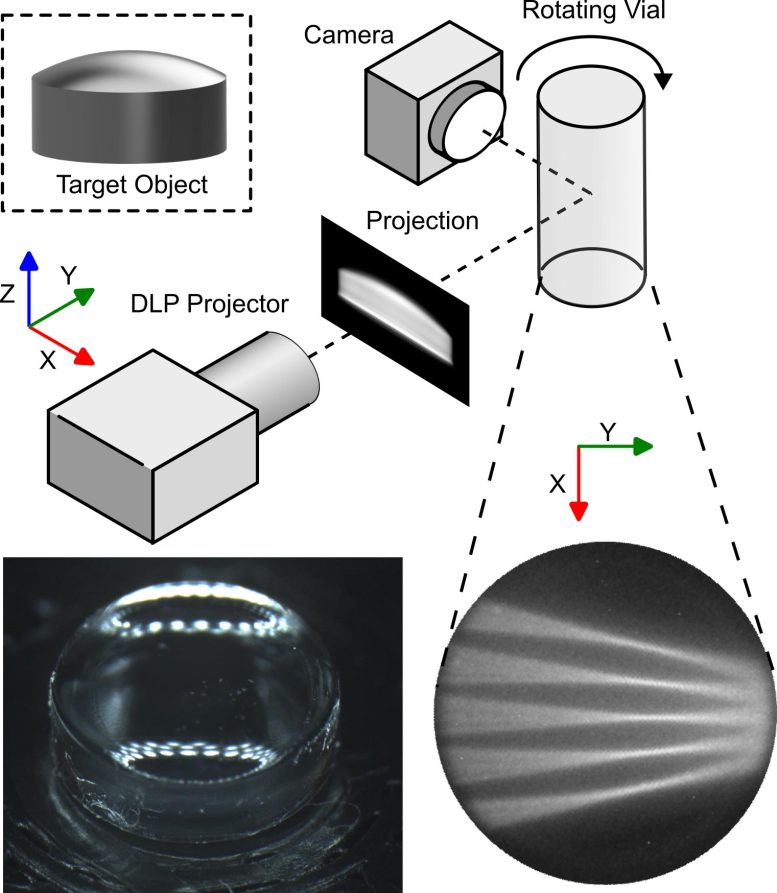

The new technique uses a custom projection lens to blur the laser beams used to solidify a light-sensitive resin. This produces an optically smooth surface, which allows commercial quality lenses to be printed such as the one shown in the bottom left. Credit: Daniel Webber, National Research Council of Canada

Smoothing Out the Edges

Tomographic volumetric additive manufacturing is a relatively new manufacturing approach that uses projected light to solidify a light-sensitive resin in specific areas. It allows an entire part to be printed at once without any support structures. However, existing tomographic methods cannot directly print imaging-quality lenses because the pencil-like beams used cause striations that lead to small ridges on the component’s surface. Although post-processing steps can be used to create smooth surfaces, these approaches add time and complexity, which takes away the rapid prototyping advantage associated with tomographic printing.

“Fabrication of optical components is costly due to the stringent technical specifications needed for a functioning lens, as well as the complex and time-consuming process of manufacturing,” said Dr. Webber. “Blurred tomography can be used to make freeform designs in a low-cost manner. As the technology matures, it could allow much quicker prototyping for new optical devices, which would be useful for anyone from commercial manufacturers to garage-based inventors.”

Creating Tiny Lenses

To test the new method, the researchers first created a simple plano-convex lens and showed that it had an imaging resolution comparable to a commercial glass lens with the same physical dimensions. It also exhibited a micron-scale form error, sub-nanometer surface roughness and a point spread function close to the glass lens.

They also made a 3×3 array of microlenses using blurred tomography and compared it to an array printed with conventional tomographic 3D printing. They found that it was not possible to image a business card with the array printed with conventional means due to large surface roughness, but it could be done with the array printed with blurred tomography. Additionally, the researchers demonstrated overprinting of a ball lens onto an optical fiber, which was previously only possible using an additive manufacturing technique known as two-SciTechDaily