The skeleton of Euplectella aspergillum, a deep-water marine sponge. Credit: Image courtesy of Matheus Fernandes/Harvard SEAS

Bioinspired architecture could pave the way for stronger, lighter structures.

When we think about sponges, we tend to think of something soft and squishy. But researchers from the Harvard John A. Paulson School of Engineering and Applied Sciences (SEAS) are using the glassy skeletons of marine sponges as inspiration for the next generation of stronger and taller buildings, longer bridges, and lighter spacecraft.

In a new paper published in Nature Materials, the researchers showed that the diagonally-reinforced square lattice-like skeletal structure of Euplectella aspergillum, a deep-water marine sponge, has a higher strength-to-weight ratio than the traditional lattice designs that have used for centuries in the construction of buildings and bridges.

“We found that the sponge’s diagonal reinforcement strategy achieves the highest buckling resistance for a given amount of material, which means that we can build stronger and more resilient structures by intelligently rearranging existing material within the structure,” said Matheus Fernandes, a graduate student at SEAS and first author of the paper.

“In many fields, such as aerospace engineering, the strength-to-weight ratio of a structure is critically important,” said James Weaver, a Senior Scientist at SEAS and one of the corresponding authors of the paper. “This biologically-inspired geometry could provide a roadmap for designing lighter, stronger structures for a wide range of applications.”

If you’ve ever walked through a covered bridge or put together a metal storage shelf, you’ve seen diagonal lattice architectures. This type of design uses many small, closely spaced diagonal beams to evenly distribute applied loads. This geometry was patented in the early 1800s by the architect and civil engineer, Ithiel Town, who wanted a method to make sturdy bridges out of lightweight and cheap materials.

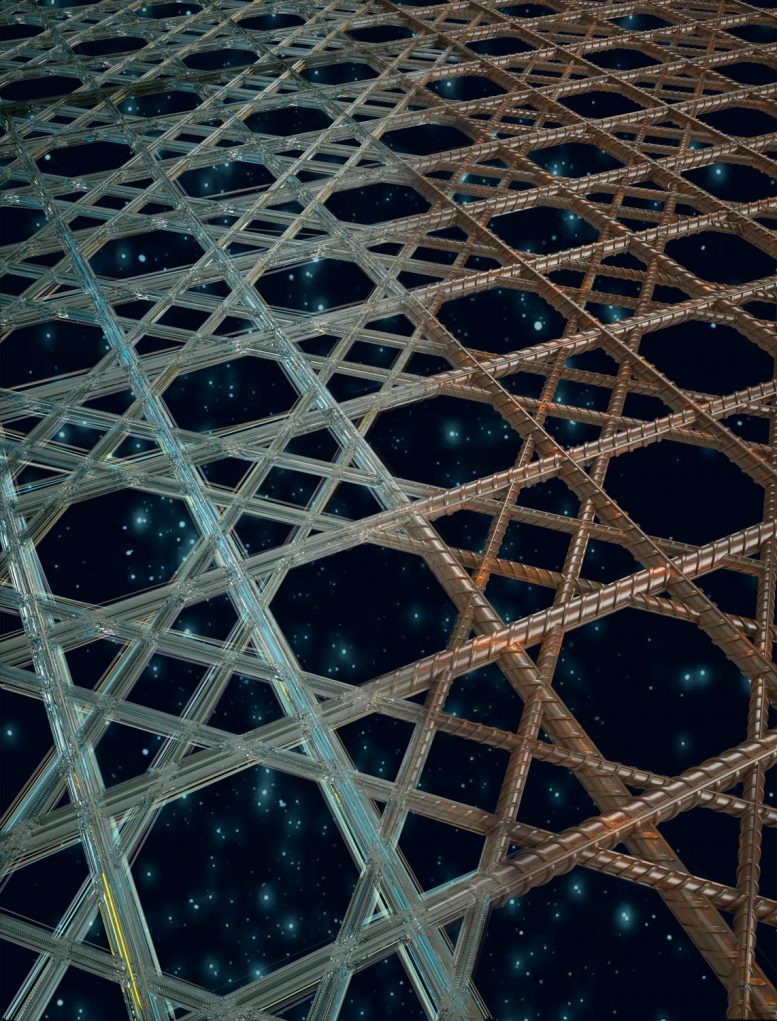

Composite rendering that transitions from a glassy sponge skeleton on the left to a welded rebar-based lattice on the right, highlighting the biologically inspired nature of the research. Credit: Image Courtesy of Peter Allen, Ryan Allen, and James C. Weaver/Harvard SEAS

“Town developed a simple, cost-effective way to stabilize square lattice structures, which is used to this very day,” said Fernandes. “It gets the job done, but it’s not optimal, leading to wasted or redundant material and a cap on how tall we can build. One of the main questions driving this research was, can we make these structures more efficient from a material allocation perspective, ultimately using less material to achieve the same strength?”

Luckily, the glass sponges, the group to which Euplectella aspergillum — otherwise known as Venus’ Flower Basket belongs — had a nearly half billion-year head start on the research and development side of things. To support its tubular body, Euplectella aspergillum employs two sets of parallel diagonal skeletal struts, which intersect over and are fused to an underlying square grid, to form a robust checkerboard-like pattern.

“We’ve been studying structure-function relationships in sponge skeletal systems for more than 20 years, and these species continue to surprise us,” said Weaver.

In simulations and experiments, the researchers replicated this design and compared the sponge’s skeletal architecture to existing lattice geometries. The sponge design outperformed them all, withstanding heavier loads without buckling. The researchers showed that the paired parallel crossed-diagonal structure improved overall structural strength by more than 20 percent, without the need to add additional material to achieve this effect.

“Our research demonstrates that lessons learned from the study of sponge skeletal systems can be exploited to build structures that are geometrically optimized to delay buckling, with huge implications for improved material use in modern infrastructural applications,” said Katia Bertoldi, the William and Ami Kuan Danoff Professor of Applied Mechanics at SEAS and a corresponding author of the study.

Reference: “Mechanically robust lattices inspired by deep-sea glass sponges” by Matheus C. Fernandes, Joanna Aizenberg, James C. Weaver and Katia Bertoldi, 21 September 2020, Nature Materials.DOI: 10.1038/s41563-020-0798-1

The Harvard Office of Technology Development has protected the intellectual property relating to this project and is exploring commercialization opportunities.

This paper was also co-authored by Joanna Aizenberg, the Amy Smith Berylson Professor of Materials Science and Professor of Chemistry & Chemical Biology at SEAS, and the research was supported in part by the National Science Foundation through the Harvard University Materials Research Science and Engineering Center DMR-2011754 and NSF DMREF Grant DMR-1922321