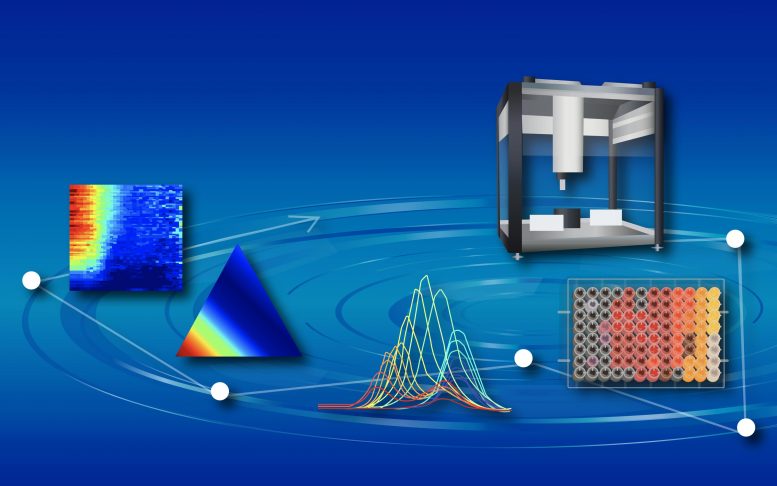

Researchers at ORNL and the University of Tennessee developed an automated workflow that combines chemical robotics and machine learning to speed the search for stable perovskites. Credit: Jaimee Janiga/ORNL, U.S. Dept of Energy

Researchers at the Department of Energy’s Oak Ridge National Laboratory and the University of Tennessee are automating the search for new materials to advance solar energy technologies.

A novel workflow published in ACS Energy Letters combines robotics and machine learning to study metal halide perovskites, or MHPs — thin, lightweight, flexible materials with outstanding properties for harnessing light that can be used to make solar cells, energy-efficient lighting and sensors.

“Our approach speeds exploration of perovskite materials, making it exponentially faster to synthesize and characterize many material compositions at once and identify areas of interest,” said ORNL’s Sergei Kalinin.

The study, part of an ORNL-UT Science Alliance collaboration, aims to identify the most stable MHP materials for device integration.

“Automated experimentation can help us carve an efficient path forward in exploring what is an immense pool of potential material compositions,” said UT’s Mahshid Ahmadi.

Although MHPs are attractive for their high efficiency and low fabrication costs, their sensitivity to the environment limits operational use. Real-world examples tend to degrade too quickly in ambient conditions, such as light, humidity or heat, to be practical.

The enormous potential for perovskites presents an inherent obstacle for materials discovery. Scientists face a vast design space in their efforts to develop more robust models. More than a thousand MHPs have been predicted, and each of these can be chemically modified to generate a near limitless library of possible compositions.

“It is difficult to overcome this challenge with conventional methods of synthesizing and characterizing samples one at a time,” said Ahmadi. “Our approach allows us to screen up to 96 samples at a time to accelerate materials discovery and optimization.”

The team selected four model MHP systems — yielding 380 compositions total — to demonstrate the new workflow for solution-processable materials, compositions that begin as wet mixtures but dry to solid forms.

The synthesis step employed a programmable pipetting robot designed to work with standard 96-well microplates. The machine saves time over manually dispensing many different compositions; and it minimizes error in replicating a tedious process that needs to be performed in exactly the same ambient conditions, a variable that is difficult to control over extended periods.

Next, researchers exposed samples to air and measured their photoluminescent properties using a standard optical plate reader.

“It’s a simple measurement but is the de facto standard for characterizing stability in MHPs,” said Kalinin. “The key is that conventional approaches would be labor intensive, whereas we were able to measure the photoluminescent properties of 96 samples in about five minutes.”

Repeating the process over several hours captured complex phase diagrams in which wavelengths of light vary across compositions and evolve over time.

The team developed a machine-learning algorithm to analyze the data and home in on regions with high stability.

“Machine learning enables us to get more information out of sparse data by predicting properties between measured points,” said ORNL’s Maxim Ziatdinov, who led development of the algorithm. “The results guide materials characterization by showing us where to look next.”

While the study focuses on materials discovery to identify the most stable compositions, the workflow could also be used to optimize material properties for specific optoelectronic applications.

The automated process can be applied to any solution-processable material for time and cost savings over traditional synthesis methods.

Reference: “Chemical Robotics Enabled Exploration of Stability in Multicomponent Lead Halide Perovskites via Machine Learning” by Kate Higgins, Sai Mani Valleti, Maxim Ziatdinov, Sergei V. Kalinin and Mahshid Ahmadi, 15 October 2020, ACS Energy Letters.DOI: 10.1021/acsenergylett.0c01749

The research was supported by the Science Alliance, a Tennessee Center of Excellence, and the Center for Nanophase Materials Sciences, a DOE Office of Science User Facility.