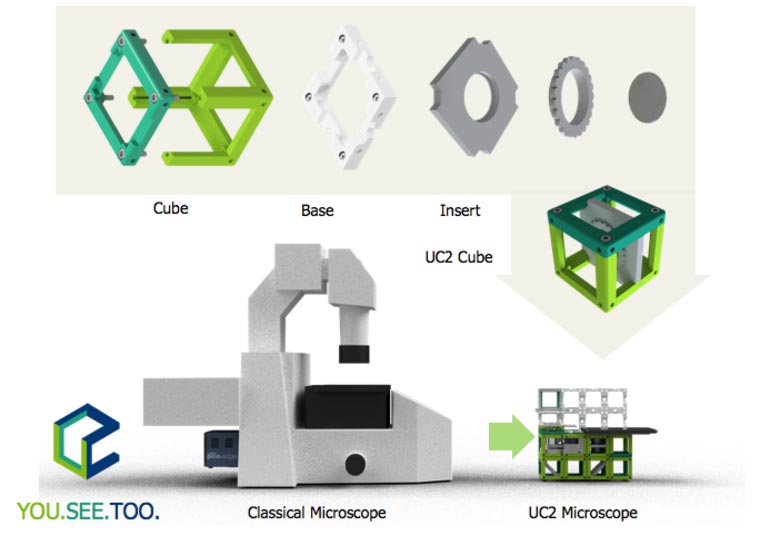

The open-source 3D-printed cube can host self-designed inserts, electrical and optical components. The resulting modules can be combined to form complex optical instruments. This allows the smartphone to be transformed into a powerful microscope in no time at all — and at almost any place on earth — in order to pose and answer completely new questions to science. Credit: UC2

The open-source system from the 3D printer delivers high-resolution images like commercial microscopes at hundreds of times the price.Modern microscopes used for biological imaging are expensive, are located in specialized laboratories and require highly qualified staff. To research novel, creative approaches to address urgent scientific issues — for example in the fight against infectious diseases such as Covid-19 — is thus primarily reserved for scientists at well-equipped research institutions in rich countries.

A young research team from the Leibniz Institute of Photonic Technology (Leibniz IPHT) in Jena, the Friedrich Schiller University and Jena University Hospital wants to change this: The researchers have developed an optical toolbox to build microscopes for a few hundred euros that deliver high-resolution images comparable to commercial microscopes that cost a hundred to a thousand times more. With open-source blueprints, components from the 3D printer and smartphone camera, the UC2 (You. See. Too.) modular system can be combined specifically in the way the research question requires — from long-term observation of living organisms in the incubator to a toolbox for optics education. The research team presents its development on November 25, 2020 in the renowned journal Nature Communications.

As powerful as a commercial microscope, as handy as a toy microscope. The UC2 development team: Benedict Diederich, René Lachmann and Barbora Maršíková (from the left) with a microscope assembled with their UC2 toolbox. Credit: Leibniz-IPHT

The basic building block of the UC2 system is a simple 3D printable cube with an edge length of 5 centimeters, which can host a variety of components such as lenses, LEDs or cameras. Several such cubes are plugged on a magnetic raster base plate. Cleverly arranged, the modules thus result in a powerful optical instrument. An optical concept according to which focal planes of adjacent lenses coincide is the basis for most of the complex optical setups such as modern microscopes.

With the UC2 toolbox, the research team of PhD students at the lab of Prof. Dr. Rainer Heintzmann, Leibniz IPHT and Friedrich Schiller University Jena, shows how this inherently modular process can be understood intuitively in hands-on-experiments. In this way, UC2 also provides users without technical training with an optical tool that they can use, modify and expand — depending on what they are researching.

Monitor pathogens — and then recycle the contaminated microscope

With UC2 users can assemble their own microscope according to the Lego principle. In this way, Benedict Diederich (left) and René Lachmann not only awaken the inner play instinct, but also open up completely new possibilities for researchers to tailor a tool precisely to their research question. Credit: Sven Döring/ Leibniz-IPHT

Helge Ewers, Professor of Biochemistry at the Free University of Berlin and the Charité, is investigating pathogens usind the UC2 toolbox. “The UC2 system allows us to produce a high-quality microscope at low cost, with which we can observe living cells in an incubator,” he states. UC2 thus opens up areas of application for biomedical research for which conventional microscopes are not suitable.

“Commercial microscopes that can be used to examine pathogens over a longer period of time cost hundreds or thousands of times more than our UC2 setup,” says Benedict Diederich, PhD student at Leibniz-IPHT, who developed the optical toolbox there together with René Lachmann. “You can hardly get them into a contaminated laboratory from which you may not be able to remove them because they cannot be cleaned easily.”

The UC2 microscope made of plastic, on the other hand, can be easily burned or recycled after its successful use in the biological safety laboratory. For a study at Jena University Hospital, the UC2 team observed the differentiation of monocytes into macrophages in the incubator over a period of one week in order to gain insights into how the innate immune system fights off pathogens in the body.

Building according to the Lego principle: From the idea to the prototype

Building according to the Lego principle — this not only awakens the users’ inner play instinct, observes the UC2 team, but it also opens up new possibilities for researchers to design an instrument precisely tailored to their research question. “With our method, it is possible to quickly assemble the right tool to map specific cells,” explains Benedict Diederich. “If, for example, a red wavelength is required as excitation, you simply install the appropriate laser and change the filter. If an inverted microscope is needed, you stack the cubes accordingly. With the UC2 system, elements can be combined depending on the required resolution, stability, duration or microscopy method and tested directly in the “rapid prototyping” process.

UC2 plus smartphone: Emilia Walther, Elias Höfling and Robin Schröder from the Montessori School in Jena assembled their own fluorescence microscope to detect microplastics in cosmetics. Barbora Maršíková (right in the picture) from the UC2 team supported them. Credit: Sven Döring/ Leibniz-IPHT

The Vision: Open Science

The researchers publish construction plans and software on the freely accessible online repository GitHub, so that the open-source community worldwide can access, rebuild, modify and expand the presented systems. “With the feedback from users, we improve the system step by step and add ever new creative solutions,” reports René Lachmann. The first users have already started to expand the system for themselves and their purposes. “We are eager to see when we can present the first user solutions.”

The aim behind this is to enable open science. Thanks to the detailed documentation, researchers can reproduce and further develop experiments anywhere in the world, even beyond well-equipped laboratories. “Change in Paradigm: Science for a Dime” is what Benedict Diederich calls this vision: to herald a paradigm shift in which the scientific process is as open and transparent as possible, freely accessible to all, where researchers share their knowledge with each other and incorporate it into their work.

UC2 box brings science to schools

In order to get especially young people interested in optics, the research team has developed a sophisticated tool set for educational purposes in schools and universities. With “The Box” UC2 introduces a kit that enables users to learn about and try out optical concepts and microscopy methods. “The components can be combined to form a projector or a telescope; you can build a spectrometer or a smartphone microscope,” explains Barbora Maršíková, who developed experiments and a series of ready-to-use documentations that the UC2 team already tested in several workshops in and around Jena as well as in the US, in Great Britain and Norway. In Jena, the young researchers have already used the UC2 toolbox in several schools and e.g. supported pupils to build a fluorescence microscope to detect microplastics. “We have combined UC2 with our smartphone. This enabled us to build our own fluorescence microscope cost-effectively without any major optical knowledge and to develop a comparably simple method for detecting plastic particles in cosmetics,” reports Emilia Walther from the Montessori School in Jena, who together with her group is pursuing an innovative interdisciplinary learning approach.

“We want to make modern microscopy techniques accessible to a broad public,” says Benedict Diederich, “and build up an open and creative microscopy community.” This build-it-yourself approach to teaching has a huge potential, especially at times of the Corona pandemics, when access to teaching material at home is severely limited.

Reference: “A versatile and customizable low-cost 3D-printed open standard for microscopic imaging” by Benedict Diederich, René Lachmann, Swen Carlstedt, Barbora Marsikova, Haoran Wang, Xavier Uwurukundo, Alexander S. Mosig and Rainer Heintzmann, 25 November 2020, Nature Communications.DOI: 10.1038/s41467-020-19447-9