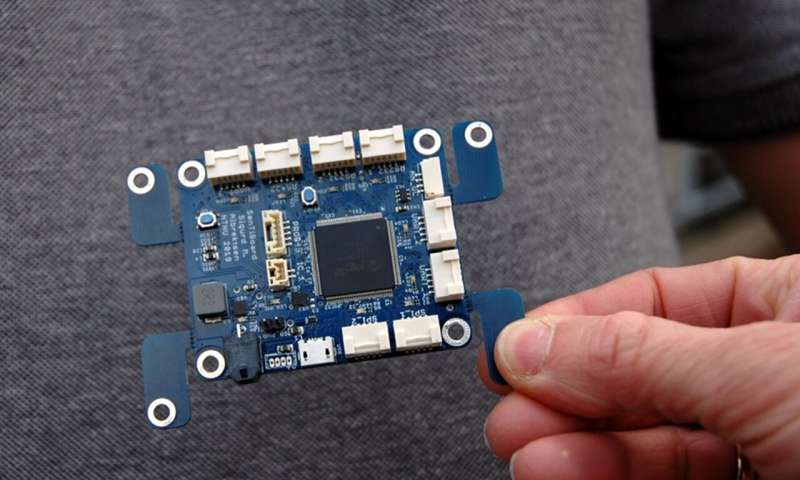

Autonomous vehicles are in demand like never before. At NTNU, researchers have developed a circuit board that can be adapted to different drones with simple steps. Airbus has tested the system on a lunar landing prototype.

SentiSystems, or SentiBoard as the circuit board itself is called, has already aroused considerable interest and been tested by one of the world’s major suppliers of transport systems.

Airbus says that the company saved a half-year of work by five people with the circuit board that they were allowed to use to make a prototype for a visual lunar landing. The company was so pleased that they ordered two more circuit boards.

Now it’s time to commercialize the technology.

The brain behind the “little brain,” as the circuit board is sometimes called, is Sigurd Mørkved Albrektsen. With a master’s degree in cybernetics and several years’ work experience at SINTEF on his resume, he began a doctorate in 2014. He planned to create algorithms for navigating drones.

“We needed a way to collect sensor data accurately, and we had to have a basis for comparison to know if the algorithms were getting better,” he says.

Despite a fairly comprehensive market research, the team didn’t find any product they could use. So Sigurd began to develop a circuit board that could read and compile the data from all the sensors.

“We discovered that the current solutions had relatively large delays which made the sensor measurements less precise. Due to the rapid movements that a drone can have, we needed a more accurate way to read sensor data than we could achieve with off-the-shelf products.

Given responsibility for 10 drones

Several researchers at NTNU were in the same situation as Albrektsen, looking for a “brain” that could control a drone super precisely and safely, but with minimal weight. They had different research assignments and each had their own problem to solve. Soon Sigurd was given responsibility for the sensor setup of ten different drones.

Some examples of sensors include GPS, accelerometers and gyroscopes (IMU), various optical systems, pressure measurement and hyperspectral cameras that can read hundreds of different colours, from infrared to ultraviolet.

Instead of creating a circuit board for each type of autonomous vehicle, which is the usual approach, he developed a circuit board that can be used on several different types. The user adapts the circuit board, or the sensor platform, for the purpose needed.

The first version of the circuit board took a few months to develop.

“It turned out to be a lot of work,” says Albrektsen. “The requirements are stringent for things like weight and processing power.”

Good support from the research community

“Our focus was to preserve the quality of the sensor measurements and make the system easy to use, so you don’t have to be a hardware expert to use it,” says Albrektsen.

He says being surrounded by others who were interested in what he was working on helped a lot. His supervisor was Professor Tor Arne Johansen, and the community at NTNU’s Department of Engineering Cybernetics is known for cheering on innovation and applied research.

“I was behind much of the idea, but Johansen was the one who got the circuit board into people’s hands. He promised it to lots of folks before it was finished,” Sigurd says. That was also a good push for him, he notes with a smile.

The SentiBoard has been used in about ten doctoral degrees and more than 20 publications. It has been tried on boats and on both fixed wing and propeller drones.

Nanosecond precision

The circuit board can read 8000 messages per second. It records measurements with ten nanosecond precision and enables different types of sensors to be flexibly integrated. Large resources around the world are now investing in and working with autonomous systems. The trend is toward increased sensor working speed.

“It’s all about development within autonomous systems, and this changes the way systems can develop. You save time and money, and the data gets better,” says Susanne Jäschke, a business developer at NTNU Technology Transfer.

“And the way you communicate with the sensors will be stable,” adds Albrektsen.

Business this fall

The plan is to establish a company to bring the technology to market. In addition to SentiBoard, the company will commercialize algorithms for sensor fusion.

NTNU Technology Transfer ensures a tidy transition from publicly funded research to private business operations. Market analysis and dialogue with potential partners is currently underway.

Erling Jellum, researcher Frederik Stendahl Leira, professor Johansen and associate professor Torleiv Håland Bryne are joining Albrektsen in establishing the business.

Jellum joined the project when he was a master’s student in cybernetics and had a part-time job searching for errors in the system that Albrektsen was building at the time. Now he has started a doctorate where he plans to further develop the circuit board.

“As it is now, SentiBoard solves some problems very well, but we want to build on the basic idea of the board. It could turn into something huge,” says Jellum.

Inspection and agriculture are among several interesting uses for the technology. The team is now looking for skilled people who want to help build it further and partner companies interested in testing the technology in various industries.