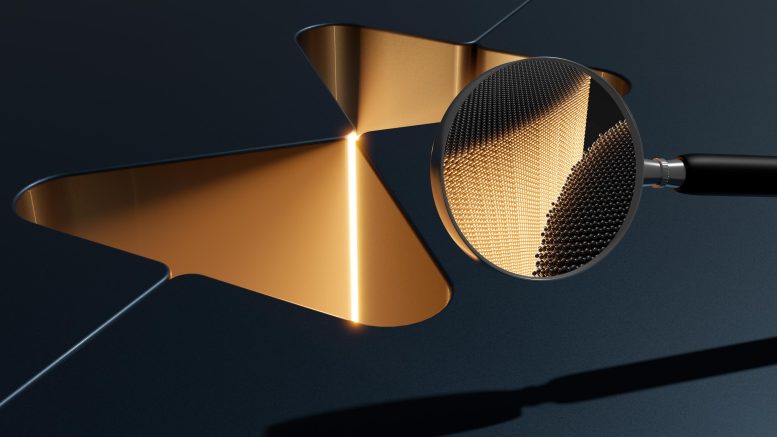

Illustration of the core of the photonic cavity that was fabricated as two halves that assembled themselves into one unit. The cavity confines light inside the gap, which is only a few atoms wide as indicated in the field of view of the magnifying glass. Credit: Thor A. S. Weis

In a new Nature paper, two nanotechnology approaches converge by employing a new generation of fabrication technology. It combines the scalability of semiconductor technology with the atomic dimensions enabled by self-assembly.

A central goal in quantum optics and photonics is to increase the strength of the interaction between light and matter to produce, e.g., better photodetectors or quantum light sources. The best way to do that is to use optical resonators that store light for a long time, making it interact more strongly with matter. If the resonator is also very small, such that light is squeezed into a tiny region of space, the interaction is enhanced even further. The ideal resonator would store light for a long time in a region at the size of a single

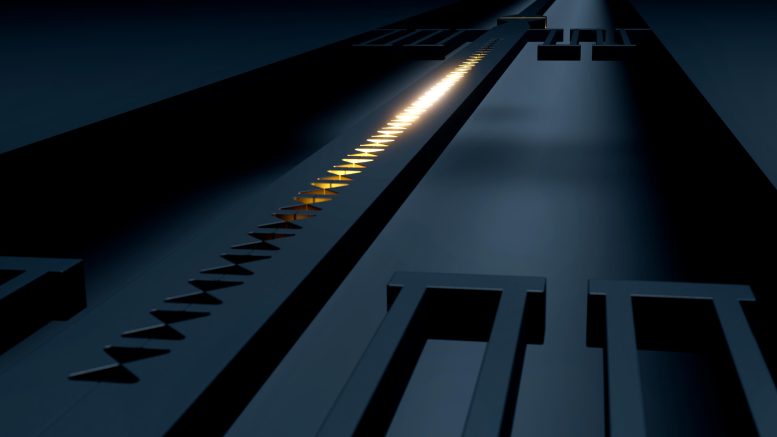

The self-assembled cavity can be integrated into larger self-assembled components for routing light around an optical chip. The figure shows the optical cavity embedded in a circuit containing multiple self-assembled elements. Credit: Thor A. S. Weis

Innovative Research from DTU Electro

The team behind a new paper in Nature, Associate Professor Søren Stobbe and his colleagues at DTU Electro demonstrated 8 nm cavities last year, but now they propose and demonstrate a novel approach to fabricate a self-assembling cavity with an air void at the scale of a few atoms. Their paper’ Self-assembled photonic cavities with atomic-scale confinement’ detailing the results is published today (December 6) in the journal Nature.

The Experiment Explained

To briefly explain the experiment, two halves of silicon structures are suspended on springs, although in the first step, the silicon device is firmly attached to a layer of glass. The devices are made by conventional semiconductor technology, so the two halves are a few tens of nanometers apart. Upon selective etching of the glass, the structure is released and now only suspended by the springs, and because the two halves are fabricated so close to each other, they attract due to surface forces. By carefully engineering the design of the silicon structures, the result is a self-assembled resonator with bowtie-shaped gaps at the atomic scale surrounded by silicon mirrors.

FACT BOX: Surface forces

There are four known fundamental forces: Gravitational, electromagnetic, and strong and weak nuclear forces. Besides the forces due to static configurations, e.g., the attractive electromagnetic force between positively and negatively charged particles, there can also be forces due to fluctuations. Such fluctuations may be either thermal or quantum in origin, and they give rise to surface forces such as the van der Waals force and the Casimir force which act at different length scales but are rooted in the same underlying physics. Other mechanisms, such as electrostatic surface charges, can add to the net surface force. For example, geckos exploit surface forces to cling to walls and ceilings.

“We are far from a circuit that builds itself completely. But we have succeeded in converging two approaches that have been traveling along parallel tracks so far. And it allowed us to build a silicon resonator with unprecedented miniaturization,” says Søren Stobbe.

Combining Top-Down and Bottom-Up Approaches

One approach – the top-down approach – is behind the spectacular development we have seen with silicon-based semiconductor technologies. Here, crudely put, you go from a silicon block and work on making nanostructures from them. The other approach – the bottom-up approach – is where you try to have a nanotechnological system assemble itself. It aims to mimic biological systems, such as plants or animals, built through biological or chemical processes. These two approaches are at the very core of what defines nanotechnology. But the problem is that these two approaches were so far disconnected: Semiconductors are scalable but cannot reach the atomic scale, and while self-assembled structures have long been operating at atomic scales, they offer no architecture for the interconnects to the external world.

The leading authors at work in the lab: Ph.D.-student Ali Nawaz Babar, postdoc Guillermo Arregui, and Associate Professor Søren Stobbe. Credit: Ole Ekelund

The Future of Self-Assembly in Nanotechnology

“The interesting thing would be if we could produce an electronic circuit that built itself—just like what happens with humans as they grow but with inorganic semiconductor materials. That would be true hierarchical self-assembly. We use the new self-assembly concept for photonic resonators, which may be used in electronics, nanorobotics, sensors, quantum technologies, and much more. Then, we would really be able to harvest the full potential of nanotechnology. The research community is many breakthroughs away from realizing that vision, but I hope we have taken the first steps,” says Guillermo Arregui, who co-supervised the project.

FACT BOX: How it was done

The paper details three experiments that the researchers carried out in the labs at DTU:

- No fewer than 2688 devices across two microchips were fabricated, each containing a platform that would either collapse onto a nearby silicon wall – or not collapse, depending upon the surface area details, spring constant, and distance between platform and wall. This allowed the researchers to make a map of which parameters would – and would not – lead to deterministic self-assembly. Only 11 devices failed due to fabrication errors or other defects, a remarkably low number for a novel self-assembly process.

- The researchers made self-assembled optical resonators whose optical properties were verified experimentally, and the atomic scale was confirmed by transmission electron microscopy.

- The self-assembled cavities were embedded in a larger architecture consisting of self-assembled waveguides, springs, and photonic couplers to make the surrounding microchip circuitry in the same process.

Advancing Self-Assembly in Nanofabrication

Supposing a combination of the two approaches is possible, the team at DTU Electro set out to create nanostructures that surpass the limits of conventional lithography and etching despite using nothing more than conventional lithography and etching. Their idea was to use two surface forces, namely the Casimir force for attracting the two halves and the van der Waals force for making them stick together. These two forces are rooted in the same underlying effect: quantum fluctuations (see Fact box).

The researchers made photonic cavities that confine photons to air gaps so small that determining their exact size was impossible, even with a transmission electron microscope. But the smallest they built are of a size of 1-3 silicon atoms.

Challenges and Prospects of Self-Assembly

“Even if the self-assembly takes care of reaching these extreme dimensions, the requirements for the nanofabrication are no less extreme. For example, structural imperfections are typically on the scale of several nanometers. Still, if there are defects at this scale, the two halves will only meet and touch at the three largest defects. We are really pushing the limits here, even though we make our devices in one of the very best university cleanrooms in the world,” says Ali Nawaz Babar, a PhD student at the NanoPhoton Center of Excellence at DTU Electro and first author of the new paper.

“The advantage of self-assembly is that you can make tiny things. You can build unique materials with amazing properties. But today, you can’t use it for anything you plug into a power outlet. You can’t connect it to the rest of the world. So, you need all the usual semiconductor technology for making the wires or waveguides to connect whatever you have self-assembled to the external world.”

Linking Nanotechnology Approaches

The paper shows a possible way to link the two nanotechnology approaches by employing a new generation of fabrication technology that combines the atomic dimensions enabled by self-assembly with the scalability of SciTechDaily