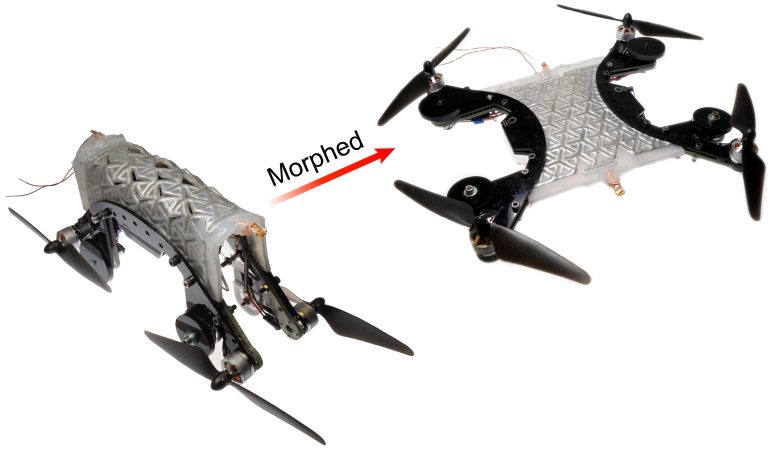

Drone able to morph and bends using liquid metal. Credit: Virginia Tech

Imagine a small autonomous vehicle that could drive over land, stop, and flatten itself into a quadcopter. The rotors start spinning, and the vehicle flies away. Looking at it more closely, what do you think you would see? What mechanisms have caused it to morph from a land vehicle into a flying quadcopter? You might imagine gears and belts, perhaps a series of tiny servo motors that pulled all its pieces into place.

See Video

If this mechanism was designed by a team at Virginia Tech led by Michael Bartlett, assistant professor in mechanical engineering, you would see a new approach for shape changing at the material level. These researchers use rubber, metal, and temperature to morph materials and fix them into place with no motors or pulleys. The team’s work has been published in Science Robotics. Co-authors of the paper include graduate students Dohgyu Hwang and Edward J. Barron III and postdoctoral researcher A. B. M. Tahidul Haque.

Getting into shape

Nature is rich with organisms that change shape to perform different functions. The octopus dramatically reshapes to move, eat, and interact with its environment; humans flex muscles to support loads and hold shape; and plants move to capture sunlight throughout the day. How do you create a material that achieves these functions to enable new types of multifunctional, morphing robots?

“When we started the project, we wanted a material that could do three things: change shape, hold that shape, and then return to the original configuration, and to do this over many cycles,” said Bartlett. “One of the challenges was to create a material that was soft enough to dramatically change shape, yet rigid enough to create adaptable machines that can perform different functions.”

To create a structure that could be morphed, the team turned to kirigami, the Japanese art of making shapes out of paper by cutting. (This method differs from origami, which uses folding.) By observing the strength of those kirigami patterns in rubbers and composites, the team was able to create a material architecture of a repeating geometric pattern.

Edward Barron, Michael Bartlett, and Dohgyu Hwang hold a piece of material that has been warped. Credit: Photo by Alex Parrish for Virginia Tech

Next, they needed a material that would hold shape but allow for that shape to be erased on demand. Here they introduced an endoskeleton made of a low melting point

I am a student of BAK College. The recent paper competition gave me a lot of headaches, and I checked a lot of information. Finally, after reading your article, it suddenly dawned on me that I can still have such an idea. grateful. But I still have some questions, hope you can help me.