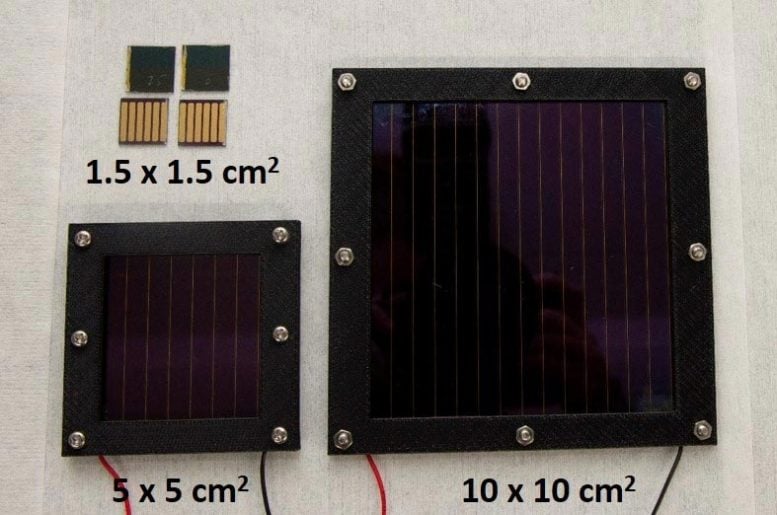

The researchers created solar modules that were 5×5 cm2 and 10×10 cm2 – much larger than the 1.5 x 1.5 cm2 ones traditionally made in a lab, but smaller than commercial solar panels. Credit: OIST

- Perovskites are projected to be a game-changer in future solar technology but currently suffer from a short operational lifespan and drops in efficiency when scaled up to a larger size

- Scientists have improved the stability and efficiency of solar cell modules by mixing the precursor materials with ammonium chloride during fabrication

- The perovskite active layer in the improved solar modules are thicker and have larger grains, with fewer defects

- Both 5 x 5 cm2 and 10 x 10 cm2 perovskite modules maintained high efficiencies for over 1000 hours

Researchers from the Okinawa Institute of Science and Technology Graduate University (OIST) have created perovskite solar modules with improved stability and efficiency by using a new fabrication technique that reduced defects. Their findings were published on the 25th of January 2021, in Advanced Energy Materials.

Perovskites are one of the most promising materials for the next-generation of solar technology, soaring from efficiencies of 3.8% to 25.5% in slightly over a decade. Perovskite solar cells are cheap to produce and have the potential to be flexible, increasing their versatility. But two obstacles still block the way to commercialization: their lack of long-term stability and difficulties with upscaling.

“Perovskite material is fragile and prone to decomposition, which means the solar cells struggle to maintain high efficiency over a long time,” said first author Dr. Guoqing Tong, a postdoctoral scholar in the OIST Energy Materials and Surface Sciences Unit, led by Professor Yabing Qi. “And although small-sized perovskite solar cells have a high efficiency and perform almost as well as their silicon counterparts, once scaled up to larger solar modules, the efficiency drops.”

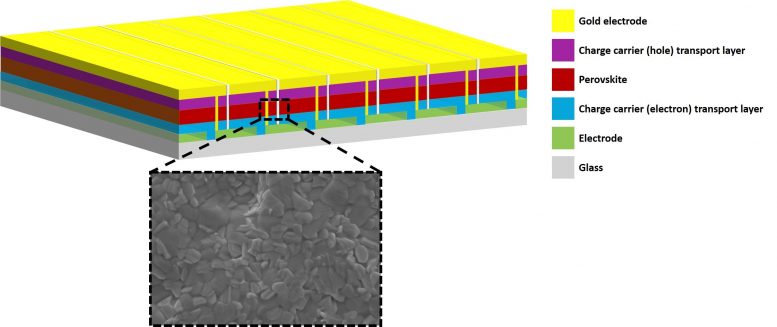

In a functional solar device, the perovskite layer lies in the center, sandwiched between two transport layers and two electrodes. As the active perovskite layer absorbs sunlight, it generates charge carriers which then flow to the electrodes via the transport layers and produce a current.

However, pinholes in the perovskite layer and defects at the boundaries between individual perovskite grains can disrupt the flow of charge carriers from the perovskite layer to the transport layers, reducing efficiency. Humidity and oxygen can also start to degrade the perovskite layer at these defect sites, shortening the lifespan of the device.

Perovskite solar cell devices require multiple layers to function. The active perovskite layer absorbs sunlight and generates charge carriers. The transport layers transport the charge carriers to the electrodes, releasing a current. The active perovskite layer is formed from many crystal grains. The boundaries between these grains, and other defects in the perovskite film, such as pinholes, lower the efficiency and lifespan of the solar devices. Credit: OIST

“Scaling up is challenging because as the modules increase in size, it’s harder to produce a uniform layer of perovskite, and these defects become more pronounced,” explained Dr. Tong. “We wanted to find a way of fabricating large modules that addressed these problems.”

Currently, most solar cells produced have a thin perovskite layer – only 500 nanometers in thickness. In theory, a thin perovskite layer improves efficiency, as the charge carriers have less distance to travel to reach the transport layers above and below. But when fabricating larger modules, the researchers found that a thin film often developed more defects and pinholes.

The researchers therefore opted to make 5 x 5 cm2 and 10 x 10 cm2 solar modules that contained perovskite films with double the thickness.

Scientists from the OIST Energy Materials and Surface Sciences Unit show off the perovskite solar modules in action, powering a fan and toy car. Credit: OIST

However, making thicker perovskite films came with its own set of challenges. Perovskites are a class of materials that are usually formed by reacting many compounds together as a solution and then allowing them to crystallize.

However, the scientists struggled to dissolve a high enough concentration of lead iodine – one of the precursor materials used to form perovskite – that was needed for the thicker films. They also found that the crystallization step was fast and uncontrollable, so the thick films contained many small grains, with more grain boundaries.

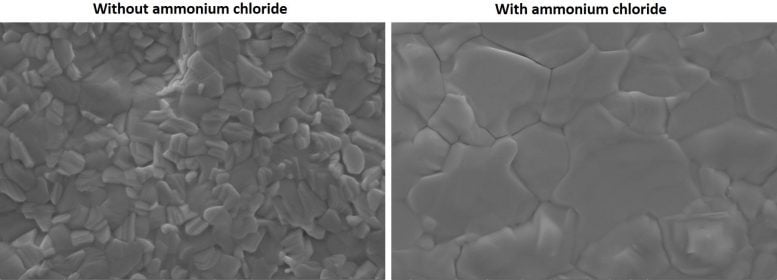

The researchers therefore added ammonium chloride to increase the solubility of lead iodine. This also allowed lead iodine to be more evenly dissolved in the organic solvent, resulting in a more uniform perovskite film with much larger grains and fewer defects. Ammonia was later removed from the perovskite solution, lowering the level of impurities within the perovskite film.

By adding ammonium chloride, the resultant perovskite film had fewer grains of a much larger size, reducing the number of grain boundaries. Credit: OIST

Overall, the solar modules sized 5 x 5 cm2 showed an efficiency of 14.55%, up from 13.06% in modules made without ammonium chloride, and were able to work for 1600 hours – over two months – at more than 80% of this efficiency.

The larger 10 x 10 cm2 modules had an efficiency of 10.25% and remained at high levels of efficiency for over 1100 hours, or almost 46 days.

“This is the first time that a lifespan measurement has been reported for perovskite solar modules of this size, which is really exciting,” said Dr. Tong.

This work was supported by the OIST Technology Development and Innovation Center’s Proof-of-Concept Program. These results are a promising step forward in the quest to produce commercial-sized solar modules with efficiency and stability to match their silicon counterparts.

In the next stage of their research, the team plans to optimize their technique further by fabricating the perovskite solar modules using vapor-based methods, rather than by using solution, and are now trying to scale up to 15 x 15 cm2 modules.

“Going from lab-sized solar cells to 5 x 5 cm2 solar modules was hard. Jumping up to solar modules that were 10 x 10 cm2 was even harder. And going to 15 x 15 cm2 solar modules will be harder still,” said Dr. Tong. “But the team is looking forward to the challenge.”

Reference: “Scalable Fabrication of >90 cm2 Perovskite Solar Modules with >1000 h Operational Stability Based on the Intermediate Phase Strategy” by Guoqing Tong, Dae‐Yong Son, Luis K. Ono, Yuqiang Liu, Yanqiang Hu, Hui Zhang, Afshan Jamshaid, Longbin Qiu, Zonghao Liu and Yabing Qi, 25 January 2021, Advanced Energy Materials.DOI: 10.1002/aenm.202003712